Why Zinc Die Casting is used for Furniture

Did you know that Zinc die casting is used for furniture applications? The furniture industry has long relied on the use of various materials to create functional and aesthetically pleasing pieces. Zinc die casted furniture parts have emerged as a popular choice for furniture manufacturers due to their versatility, strength, and durability. Zinc die castings are made by injecting molten zinc alloy into a mold cavity at high pressure, creating a precise and detailed part. This casting process produces complex shapes with excellent surface finishes, making zinc die castings ideal for a wide range of furniture applications.

Main Benefits of Zinc Die Casting for Furniture Manufacturing

One of the main benefits of using zinc die castings in the furniture industry is their strength and durability. Furniture is subjected to various stresses and strains, from the weight of occupants to the impact of accidental bumps and knocks. This means that durable furniture needs components that can handle the level of strain and stress.

Zinc die casted parts can more easily withstand these forces, making them ideal for furniture components such as legs, casters, and hinges. Zinc is a strong and rigid metal material that can withstand high levels of stress and strain without deforming or cracking, making it a reliable choice for furniture manufacturers.

Zinc is also beneficial because it is not just a simple material, instead Zinc alloys are used like Zamak 3, Zamak 5, and Zamak ??. A single material can have more weaknesses and less benefits than a metal alloy. Zinc alloys combine the strengths and benefits of several different materials. Making parts of Zinc alloys more reliable than furniture parts of a single metal material.

Increased Design Accuracy with Zinc Die Casting

Another advantage of zinc die castings is their ability to provide a high level of accuracy in design, and consistency in production. Furniture manufacturers need components that fit together correctly and function properly to create high-quality furniture. Zinc die castings can be produced to very precise specifications, ensuring that they meet the requirements of furniture manufacturers in terms of fit, finish, and functionality. This precision is particularly important for furniture that requires precise measurements, such as drawer handles and knobs.

In addition to their strength and precision, zinc die castings offer a wide range of design possibilities. Furniture manufacturers can create complex shapes and intricate designs using zinc die castings, making them ideal for decorative components such as trim, handles, and knobs. Zinc die castings can also be plated with a range of finishes, such as chrome, nickel, brass, and copper, allowing furniture manufacturers to create hardware components that are both functional and aesthetically pleasing.

Common Furniture Parts Made with Zinc Die Casting

Zinc die castings are also widely used in the production of upholstery hardware, such as buckles, buttons, and hooks. These components require strength, as they are subjected to constant use and can be subject to high levels of stress and strain. These product types often require a decorative finish which, as noted above, is a benefit of high-pressure zinc casting. Zinc die castings can provide the necessary strength and durability for these components, ensuring that they function properly and can withstand the demands of daily use.

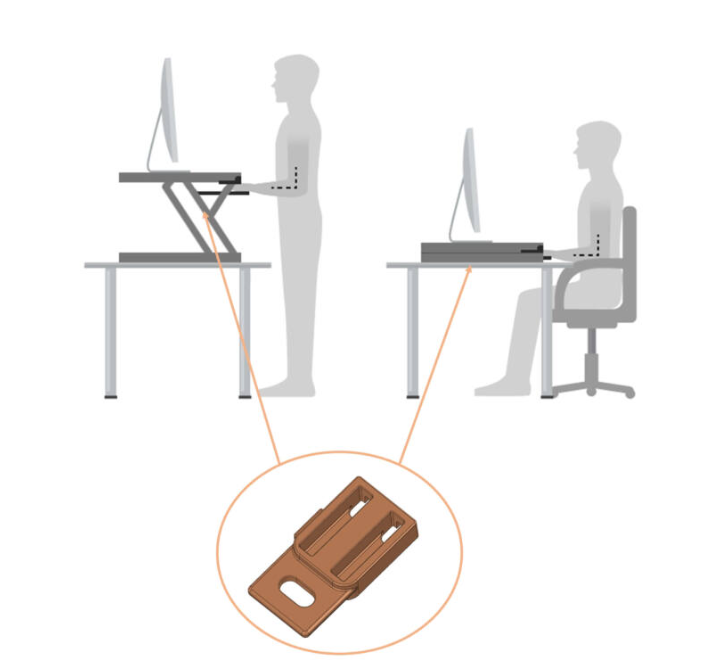

The use of zinc die castings in the furniture industry is also growing in the production of office furniture. Components such as hinges, locks, and drawer slides require a high level of durability in order to function properly and withstand the demands of daily office use. Zinc die castings provide the necessary strength and durability for these components, as well as the precision and accuracy required for correct fit and functionality.

Manufacturing Lighting Fixtures with Zinc Alloy Parts

Zinc die castings are also used in manufacturing lighting fixtures for furniture. These components are often unique in design to create a functional and aesthetically pleasing look. Zinc die castings can provide the necessary shape for the production of these lighting fixture components. Lighting fixtures also may require head dissipation components, or heat sinks. Zinc alloys are highly conductive and can be cast with thin walls which is an excellent solution for heat sinks.

Designing Outdoor Furniture with Zinc Parts

Another area where zinc die castings are commonly used in the furniture industry is in the production of outdoor furniture. Outdoor furniture is exposed to various weather conditions and must be able to withstand the elements in order to remain functional and aesthetically pleasing. Zinc die castings, when finished properly, are highly resistant to corrosion. Painting with powder coat or wet paint, e-coat or plating are often used in outdoor applications. For these reasons we see zinc as an ideal choice for outdoor furniture components such as table legs, frame components, and hardware.

Choose Cast Products for Your Furniture Parts Zinc Die Casting

Overall, the use of Zinc die castings in the furniture industry offers a wide range of benefits, including design flexibility, strength, and decorative properties. Zinc alloys provide increased strength and more benefits than other furniture materials.

Zinc die casting process provides repeatability in production to meet quality and volume demands of the furniture industry. If you have a furniture application, please contact us at Cast Products via the Get Quote or Ask An Expert buttons on our website.

Proudly Made in the U.S.A.

Proudly Made in the U.S.A.